Een neutraal en open klinkende ineterconnect Lees meer.

Plan kosteloos een luisterafspraak. Of heb je hulp nodig bij je bestelling? Neem contact op met onze klantenservice.

1 meter set demo van € 595,- voor € 349,-

ArNi® wire was designed by Shunyata Research to be the finest quality wire available. It begins with the highest purity of copper and silver metals available, including Ohno (single crystal), PCOCC silver and OFE C0101 conductors. Fluorocarbon dielectrics, usually only found in aerospace applications that have exceptional electrical characteristics including extremely low dielectric absorption, high dielectric strength and superb heat resistance. When used in digital wiring it significantly reduces transient energy storage and release which affects phase noise performance. And finally every cable undergoes our proprietary KPIP™ process.

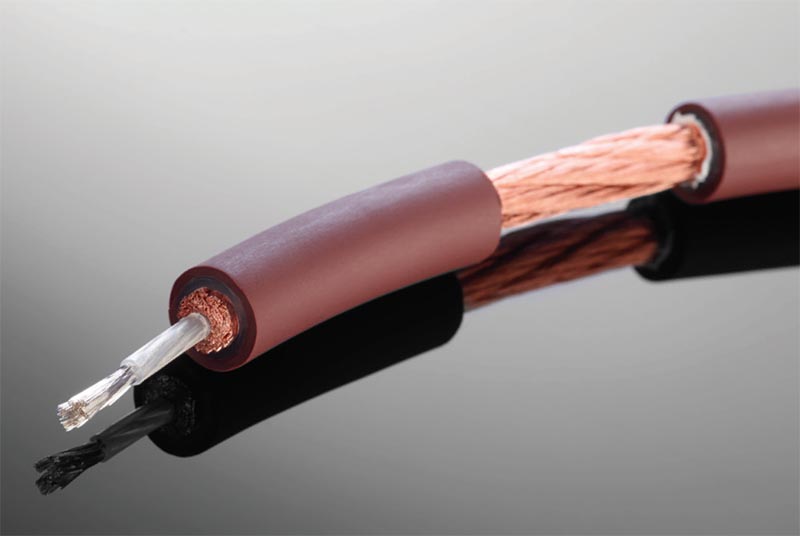

VTX-Ag cables are uniquely constructed with both an inner, center conductor made of pure silver and an outer concentric ring conductor made of pure copper. It is made using the finest fluorocarbon insulation to minimize dielectric absorption and re-radiation which translates to an improvement in resolution and clarity. VTX-Ag delivers the speed and clarity of silver and the midrange warmth and three dimensional power in the lower octaves of copper without imparting any of the negatives associated with either metal. The best qualities of silver and copper combined.

Ohno wire, also called PCOCC was invented in 1986 by professor Atsumi Ohno of the Chiba Institute of Technology in Japan. Copper wire is created by an extrusion process that pulls a rod of cold copper through a small orifice which creates multiple crystalline boundaries. By contrast, Ohno wire is made by a process using heated molds that cast a wire to form a single crystalline structure. Ohno wire is well known for its exceptionally pure, grain-free sonic qualities. Single-crystal purity

Kinetic Phase Inversion Processing was developed by Caelin Gabriel after years of research into the underlying causes of various effects such as burn-in, wire directionality and the effects of cryogenic treatment. He discovered that there was an underlying core principle that burn-in and cryogenics only partially addressed. Once the governing principle was understood it became possible to create a processor that reduces the need for long burn-in periods and eliminates the effects of cryogenic treatment. Four-days of continuous KPIP™ processing dramatically reduces the sonic ups and downs associated with burn-in, delivering a relaxed and natural presentation.

Specifications

- Cable Type: VTX coaxial

- Conductors: ArNi® / VTX / Ohno

- Dielectric: TPE

- Connectors: SR-RCA-v

- TAP Modules: NA

- KPIP Processing: 4-days

- Standard Length: 1.00 meters

- Safety Assurance: Continuity and polarity tests – by two technicians

HiPOT tests insulation breakdown @ 1,200 VAC